Glass Bricks

Harzkristall is one of the last remaining glassworks in Germany that is still producing. In addition to classic Falconnier glass bricks, Harzkristall produces high-grade lighting glass for private and commercial customers.

Falconnier glass bricks

Falconnier glass bricks are mostly used in historic preservation projects. The bricks offer a certain level of thermal insulation thanks to the partial vacuum.

Falconnier blow-moulded

glass bricks

Falconnier glass bricks bear the name of their inventor, Gustave Falconnier, who invented and produced mouth-blown glass in 1880. Even then, airtight sealed bricks already distinguished themselves by their light weight and heat-insulating effect.

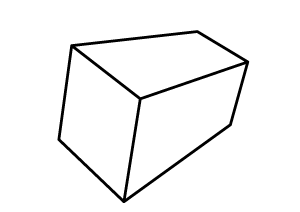

Falconnier glass bricks are blown in a three-part fixed blowing steel mould. The glass brick is sealed airtight with a drop of molten glass. This creates a partial vacuum upon cooling which increases the glass brick's heat-insulating effect. The rhombic structure makes the bricks stable and robust.

Harzkristall has already made classic Falconnier glass bricks for a wide range of different projects. The company already produced about 8,000 bricks for the renovation of Göttingen's locomotive hall back in 1996. It also made identical bricks in 2017 for the restoration of the Schappe Süd youth and culture centre in Switzerland, which required 400 mould-blown glass bricks.

Pressed glass bricks

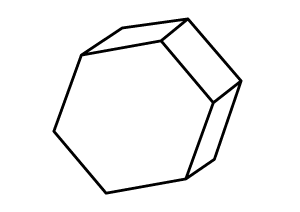

In construction projects, glass bricks are often made as pressed bricks as well. Whether square, rectangular or round: glass bricks are used both indoors and out. They are especially versatile for indoor use.

Facades of old houses in particular had long been made with glass brick walls. Nowadays, however, they are only still used in restorations on account of their poorer insulating properties. But especially indoors, where insulation is less important, the bricks are increasingly being used as a translucent design element.

The glass is removed at 1200°C during production and poured into a metal mould. This can have a plain and simple design, or it can be decorated with a special pattern. The molten glass then flows into the mould and is compressed at high pressure, which is what gives the brick its contours. After that, the bricks are cooled down in a cooling kiln at 500 °C, and can then be installed.

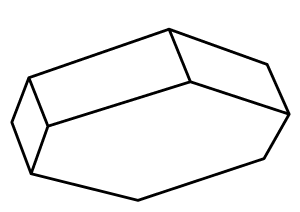

Cast glass bricks

Nowadays, cast glass bricks are used almost exclusively in the field of historic conservation.

A solid metal mould is poured full of molten glass at 1300 °C. The glass takes the desired shape through the high temperature during production.

Glass bricks of this kind are usually much heavier than pressed bricks, often weighing up to 10 kg per brick. The glass bricks can be moulded into oblong, square or even round shapes.